The Manufacturing Process Of Concrete

The manufacture of concrete is fairly simple. First, the cement (usually Portland cement) is prepared. Next, the other ingredients—aggregates (such as sand or gravel), admixtures (chemical additives), any necessary fibers, and water—are mixed together with the cement to form concrete. The concrete is then shipped to the work site and placed, compacted, and cured.

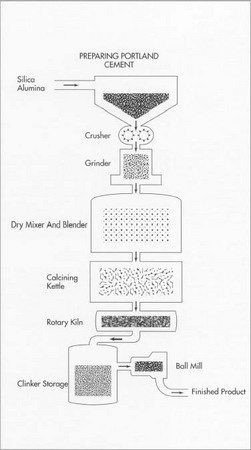

Preparing Portland cement

- 1 The limestone, silica, and alumina that make up Portland cement are dry ground into a very fine powder, mixed together in predetermined proportions, preheated, and calcined (heated to a high temperature that will burn off impurities without fusing the ingredients). Next the material is burned in a large rotary kiln at 2,550 degrees Fahrenheit (1,400 degrees Celsius). At this temperature, the material partially fuses into a substance known as clinker. A modern kiln can produce as much as 6,200 tons of clinker a day.

- 2 The clinker is then cooled and ground to a fine powder in a tube or ball mill. A ball mill is a rotating drum filled with steel balls of different sizes (depending on the desired fineness of the cement) that crush and grind the clinker. Gypsum is added during the grinding process. The final composition consists of several compounds: tricalcium silicate, dicalcium silicate, tricalcium aluminate, and tetracalcium aluminoferrite.

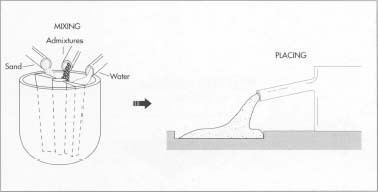

Mixing

- 3 The cement is then mixed with the other ingredients: aggregates (sand, gravel, or crushed stone), admixtures, fibers, and water. Aggregates are pre-blended or added at the ready-mix concrete plant under normal operating conditions. The mixing operation uses rotation or stirring to coat the surface of the aggregate with cement paste and to blend the other ingredients uniformly. A variety of batch or continuous mixers are used.

- 4 Fibers, if desired, can be added by a variety of methods including direct spraying, premixing, impregnating, or hand laying-up. Silica fume is often used as a dispersing or densifying agent.

Transport to work site

- 5 Once the concrete mixture is ready, it is transported to the work site. There are many methods of transporting concrete, including wheelbarrows, buckets, belt conveyors,

The first step in making concrete is to prepare the cement. One type of cement, Pordand cement, is considered superior to natural cement because it is stronger, more durable, and of a more consistent quality.

To make it, the raw materials are crushed and ground into a fine powder and mixed together. Next, the material undergoes two heating steps—calcining and burning. In calcining, the materials are heated to a high temperature but do not fuse together. In burning, however, the materials partially fuse together, forming a substance known as "clinker." The clinker is then ground in a ball mill—a rotating steel drum filled with steel balls that pulverize the material.special trucks, and pumping. Pumping transports large quantities of concrete over large distances through pipelines using a system consisting of a hopper, a pump, and the pipes. Pumps come in several types—the horizontal piston pump with semi-rotary valves and small portable pumps called squeeze pumps. A vacuum provides a continuous flow of concrete, with two rotating rollers squeezing a flexible pipe to move the concrete into the delivery pipe.

After the Portland cement is prepared, it is mixed with aggregates such as sand or gravel, admixtures, fibers, and water. Next, it is transfered to the work site and placed. During placing, segregation of the various ingredients must be avoided so that full compaction—elimination of air bubbles—can be achieved.

Placing and compacting

- 6 Once at the site, the concrete must be placed and compacted. These two operations are performed almost simultaneously. Placing must be done so that segregation of the various ingredients is avoided and full compaction—with all air bubbles eliminated—can be achieved. Whether chutes or buggies are used, position is important in achieving these goals. The rates of placing and of compaction should be equal; the latter is usually accomplished using internal or external vibrators. An internal vibrator uses a poker housing a motor-driven shaft. When the poker is inserted into the concrete, controlled vibration occurs to compact the concrete. External vibrators are used for precast or thin in situ sections having a shape or thickness unsuitable for internal vibrators. These type of vibrators are rigidly clamped to the formwork, which rests on an elastic support. Both the form and the concrete are vibrated. Vibrating tables are also used, where a table produces vertical vibration by using two shafts rotating in opposite directions.

Curing

- 7 Once it is placed and compacted, the concrete must cured before it is finished to make sure that it doesn't dry too quickly. Concrete's strength is influenced by its moisture level during the hardening process: as the cement solidifies, the concrete shrinks. If site constraints prevent the concrete from contracting, tensile stresses will develop, weakening the concrete. To minimize this problem, concrete must be kept damp during the several days it requires to set and harden.

0 comments:

Post a Comment